01.

Supplier

accreditation

02.

Pasteurization

phase

03.

The cream

ripening process

04.

Production and the NIRS system

05.

The packaging process

06.

Our packaging lines

07.

Quality

control

08.

Product

storage

01. Supplier accreditation

Follows a strict selection process in order not to compromise on the total quality level of the end product: as safeguarding the consumer is our top priority.

Checking the raw materials

Incoming refrigerated cream tanks

Incoming refrigerated cream tanks

02. Pasteurization

Is carried out in compliance with the strictest rules of best manufacturing practice. Continuous monitoring ensures constant recording of temperature and incoming and outgoing pressure.

Pasteurized cream conveyor lines

Pasteurization plant

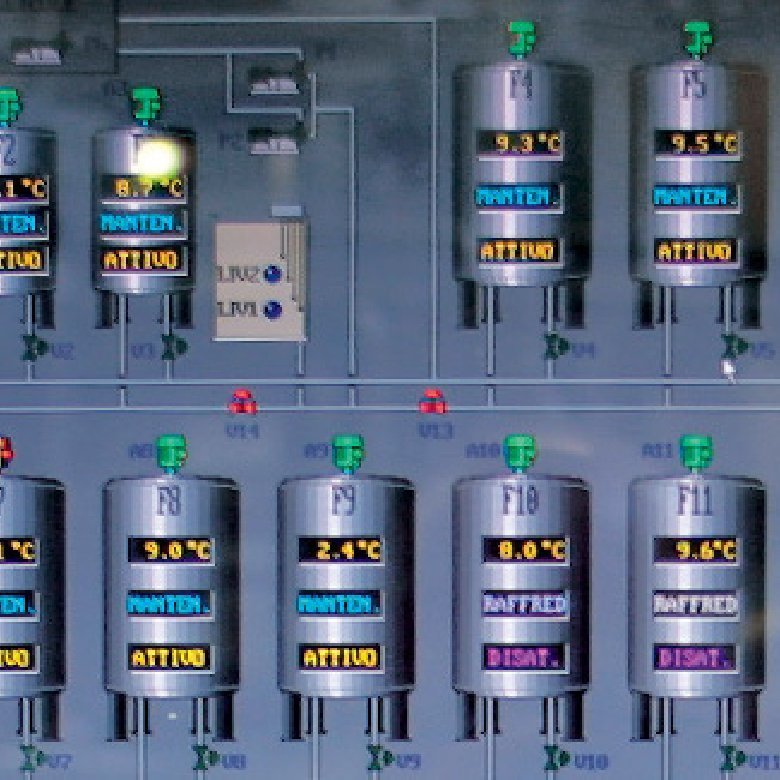

03. The cream ripening process

Begins with the addition of the ferment to the ripening tanks. The cream’s chemical/physical parameters are constantly monitored to ensure optimum development of the live milk enzymes.

Pasteurized cream ripening tanks

Detail of the ripening tanks

Ripening tank eclectronic controller

4. Production and the NIRS system

Direct human contact is prevented throughout the production cycle in order to avoid the minimum risk of bacterial contamination of the product. The NIRS system carefully monitors all the chemical parameters at intervals of only one minute.

NIRS in-line monitoring system

(legal parameters)

Butter homogeniser

Parameter monitoring by the NIRS system

Churning plants

(Kart)

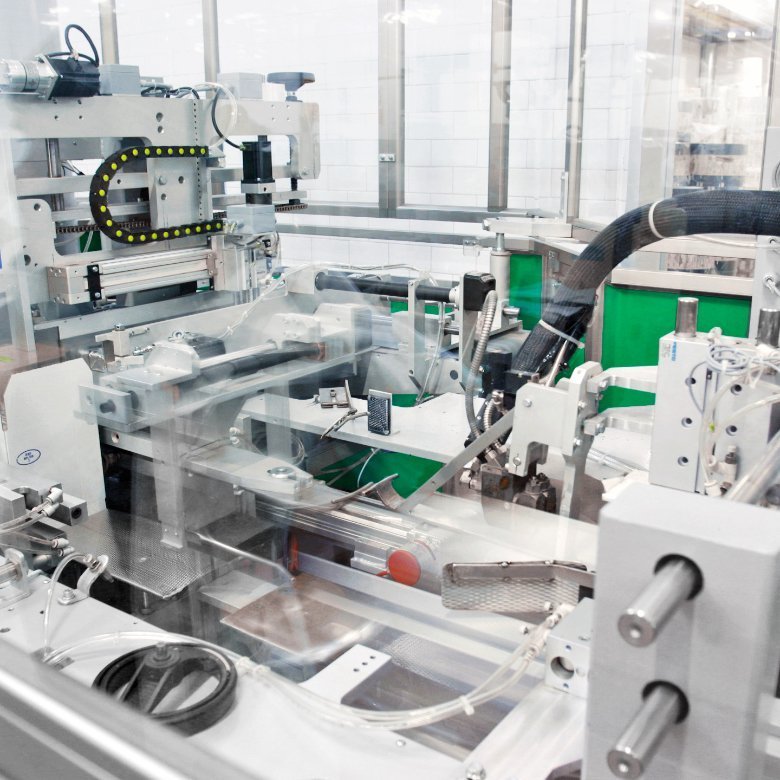

5. The packaging process

Is continuous, planned and monitored in every detail. The butter is checked at all the critical points to prevent contamination risks during storage after the churning stage, and during conveyance to the packaging room.

NIRS in-line monitoring system (legal parameters)

Butter homogeniser

NIRS in-line monitoring system (legal parameters)

Butter homogeniser

6. Our packaging lines

Operate at high speed for all the formats. Automatic packaging and instant weight control take place in a positive pressure environment where the air is filtered and the temperature is constant.

High-speed packaging machine

Automatic packaging in single-dose 125g batches

Automatic boxing machine

7. Quality control

Is ensured by the observance of strict procedures. The assessment techniques and methods guarantee the maximum chemical and microbiological safety of the packed products at all times.

Quality control laboratory: finished product analysis

Quality control laboratory: microbiological analyses

Chemical analyses

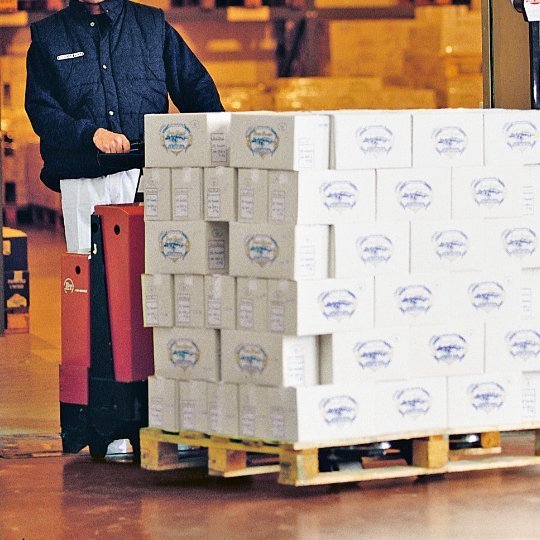

8. PRODUCT STORAGE

Takes place in temperature-controlled rooms separate from the product handling and truck leading areas.

Finished product storage rooms

Cold storage temperature control display